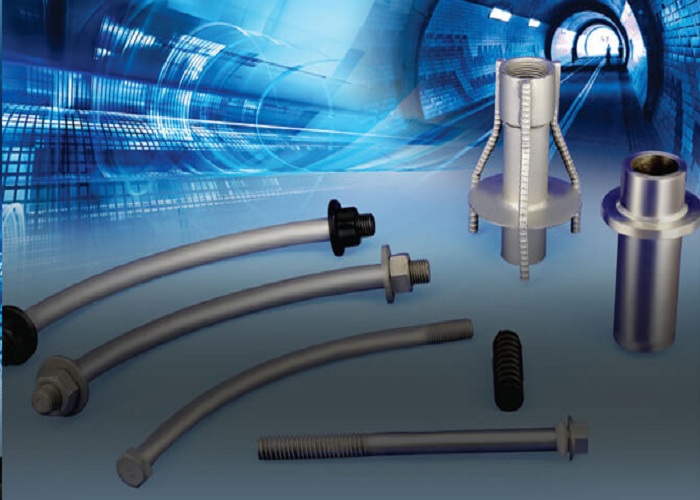

Tunnel Bolts:

Nowadays, tunnels are in construction for sewer management, underwater transport, and for storage purposes. Tunnel segment bolts are a particular type of bolts which are also known as structural bolts. These are classified into different sizes, load capacities, and grades. Tunnel bolt is used to provide transportation through underground tunnels by binding several posts and metal beams that are strong enough to build the tunnel’s frame. It is an essential component that is responsible for the overall integrity of the tunnel structure.

The components under this category are mentioned below:

> Spear Bolts and Sockets

> Banana Bolts/ Curved Tunnel Bolts

> T-Head Bolts

> Rock Bolts

> Customized Bolts

> U-Bolts

These bolts can be classified into different grades which include:

> Mild Steel

> High Tensile Steel

> Stainless Steel

The different types of coating that can be applied to these bolts are:

> Galvanized Coating

> Sherardized Coating

> Bright Zinc Coating

> Other Specialist finishes

Spear Bolts and Sockets:

Spear bolts and sockets are the equipment used to fix the tunnel segments together permanently and are located at the circumferential and radial joints of the tunnel. They are available in varied lengths, weight, size, and diameters. They are similar in function when compared to curved bolts. An advantage of this type of bolt is that after finishing, it requires only a single installation per bolt. These bolts are available in either a galvanized or a sherardized finish. They are available in different diameters, such as M16 to M30.

Banana Bolt:

These bolts are also known as curved tunnel bolts. They are found both at the radial and circumferential joints of a tunnel. The diameters of these bolts range from M16 to M30. They are available in different types of finishes and grades, such as Mild Steel and High-Tensile Steel. Banana bolts are utilized to fix the segments of a tunnel permanently.

Rock Bolt:

A rock bolt is also known as an anchor bolt. These rock bolts are used to transfer the load from an unstable surface to a more stable and stronger coating. It holds stabilization inside tunnels and rock cuts. The architecture of a rock bolt includes two ends. One end is attached to the faceplate and a nut. The other side contains a threaded steel rod attached with a mechanical or chemical anchor. These bolts are used as temporary support in mechanisms such as rock stabilization, ground support, and anchorages inside a rock.

T-Head Bolt:

T-Head bolts are generally black oxidized and commonly used as fasteners in tunneling. They can also be a dichromate, or even Rupert coated and hot-dipped galvanized. T Bolts that contain a flat head are supplied in low grade, whereas the thick T Bolts are provided to a higher degree. When there is a shaft being constructed, these bolts are used by applying the underpinning method. Every connection that involves either the process of tensioning or clamping requires such as bolts. These bolts can be found in a range of grades and finishing.

U-Bolts:

U-Bolts are used for various industrial applications. Such applications include conduit support, piping support, engine, and motor fasteners. These bolts are tied up with screw threads on both ends. They are mostly utilized for holding ropes together. These bolts are designed to support pipelines, which allow the flow of gases and fluids through it.

Customized Bolts:

Customers sometimes demand bolts to be customized as per their needs. These bolts differ in grade and finish and are designed as per the requirement.

Some features provided by Tunnel Bolts are

1. High durability and high corrosion resistance– these bolts are designed in such a manner as to provide and ensure high resistance from factors such as rust and friction.

2. Most Cost-effective– Are available at affordable prices.

3. Provides high consistency – They provide superior quality and high consistency throughout their lifetime.

Advantages:

1. Tunnel segments are responsible for maintaining the overall integrity of the tunnel structure.

2. They are one of the essential components in this mechanism.

3. Rock bolts are in utilization in varied fields such as rock stabilization, ground support, anchorages in a rock.

4. Spear bolts are mandatory for the permanent fixing of the tunnel segments.